Models

| Model | L/D Ratio | Motor Power [kW] | Screw Speed [rpm] | PVC-U Capacity Min. [kg/h] | PVC-U Capacity Max. [kg/h] |

|---|---|---|---|---|---|

| MCV 55/20D | 20 | 16 | 35 | 30 | 80 |

| MCV 67/22D | 22 | 27 | 35 | 60 | 140 |

| MCV 68/25D | 25 | 27 | 35 | 80 | 200 |

| MCV 75/25D | 25 | 33 | 35 | 120 | 250 |

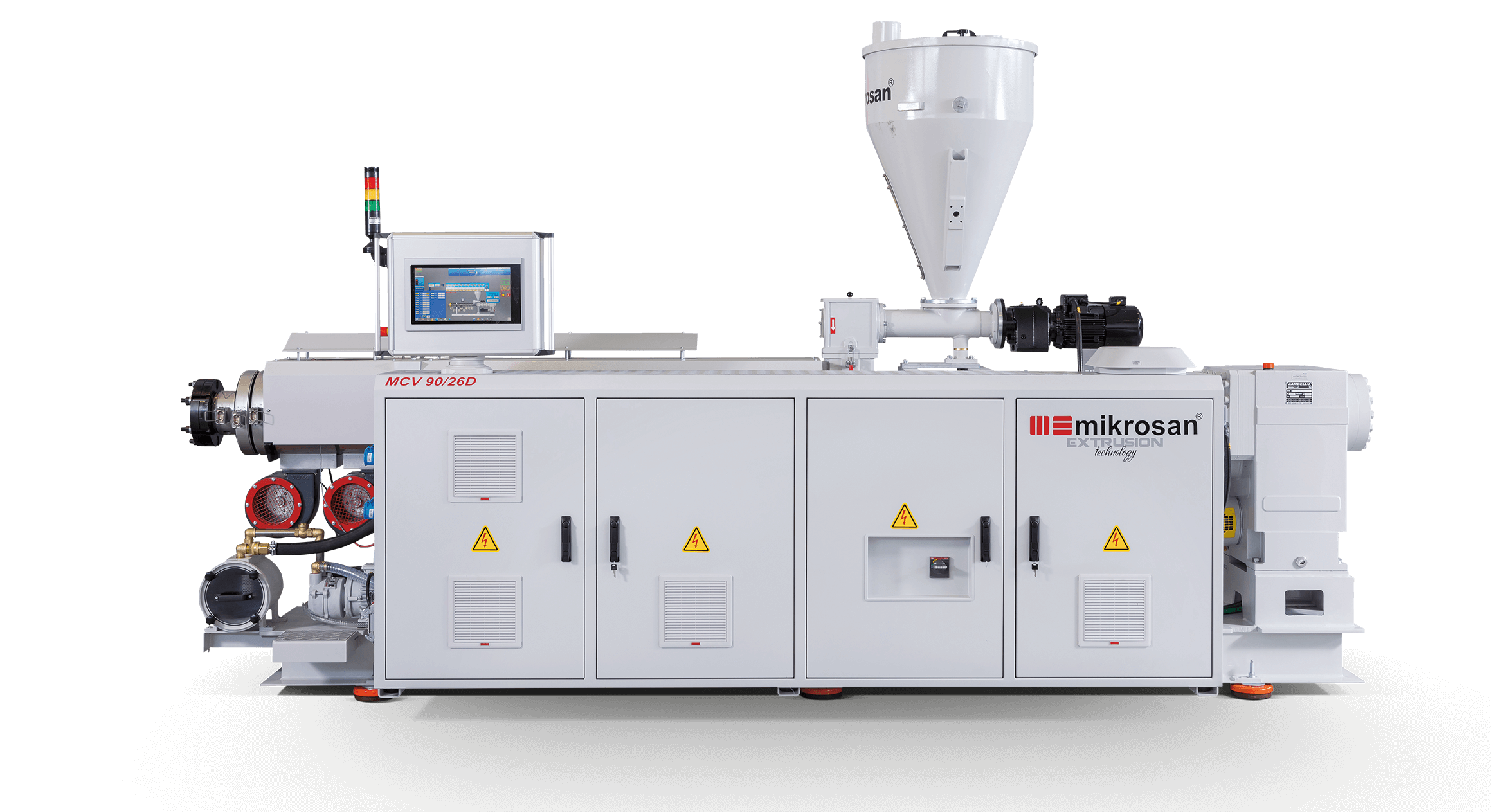

| MCV 90/26D | 26 | 53 | 35 | 160 | 400 |

| MCV 90/33D | 33 | 62 | 35 | 200 | 500 |

| MCV 110/25D | 25 | 79 | 32 | 300 | 700 |

| MCV 135/33D | 33 | 146 | 25 | 500 | 1200 |

- Touchscreen control panel

- User-friendly interface developed by Mikrosan

- AC servo motor and driver

- High-torque gearbox

- Water-cooled screw temperature control

- Degassing zone

- Optimized dosing system for stable feeding of powder PVC material into the extruder

- Components of Turkish and European origin

Advantages

- The pipe series parallel twin-screw extruders feature proven, powerful machine technologies designed for continuous and high-efficiency production.

- The screws and barrels are specially designed according to the application and customer requirements.

- The screws and barrels are entirely manufactured within Mikrosan, including heat treatment and nitriding processes.